Students Get to ‘See Their Future’ in Manufacturing

SALEM, Ohio – The beeps of numerous backing forklifts, the whirl of injection plastic molding and laser welding machines and the smell of fresh paint greeted high school students touring Ventra Salem on Wednesday.

Ventra Salem is part of the Flex-N-Gate family of manufacturing plants owned by Shahid Kahn, who purchased Flex-N-Gate in 1980. The company has 69 manufacturing plants across the country, with 26,000 employees.

In Salem, the facility employs about 780 people, making it the second largest employer in Columbiana County, according to Bill Dustman, Ventra engineering manager. He showed the students some of the injection molded parts, mostly large facia parts and interior and exterior trim components for the vehicle industry, including many Ford, Chevrolet, Cadillac, Toyota, GMC, Buick and Rivian vehicles. Dustman said the plant is already quoting business for 2027 model lines of vehicles.

As vehicle lines are phased in and out and Ventra competes with overseas companies to create these parts, Dustman said he has seen the plant evolve and predicts it will continue to evolve. He explained to the students that their interest and knowledge of technology will help them in a manufacturing job in the future.

During their tour of the plant, students got a chance to see the tiny plastic pellets used in Ventra’s manufacturing process, witness rows of parts inspected and cleaned as they headed toward the painting area and watch robots painting those parts with precision in one of more than 100 different colors Ventra uses. More than 80 robots assist in the manufacturing process at the plant.

Forklift operators zipped past, moving pallets of finished products to the loading area for delivery. Although the United Auto Workers strike has slowed how many parts are being needed, Dustman says they have been loading the finished parts into all the empty containers so they will be ready as soon as vehicle manufacturing resumes.

“When I first started here, I couldn’t even fathom how many parts we were making, and it’s just gotten busier,” said Dustman, who notes about 70,000 parts leave the plant each day and the plant garners $132 million in sales annually.

During the tour, Dustman introduced the students to several of the longtime employees, some with more than 40 years of experience.

Dustman also explained the training programs at Ventra, including possible apprenticeships in maintenance and the tool and die fields, as well as training for process technicians, automation and supervisors. He notes the company likes to grow employees from within, and many stay for their careers.

“I think it’s very important for us to make a connection early on in their lives to show them what we’re capable of doing here, manufacturing-wise, right nearby,” Dustman said of the students. “A lot of people don’t even realize this place exists. … We’ve got many employees who have been here 40 or 50 years now, and many others who are 20 years plus. It’s hard to get them past that [first] two years, but once you get them past that two years, everybody gets into their niche. And they can evolve and better themselves with different positions as long as they apply themselves.”

About 80 high school students from across Columbiana County participated in the Manufacturing Your Future Event, giving them the opportunity to learn about manufacturing companies in the county and the training opportunities to help them get there.

Besides Ventra Salem, students had the opportunity to tour Butech Bliss, Hickey Metal Fabrication, CTM Labeling Systems, Quality Water Systems, MAC Trailer, Compco and Humtown Products.

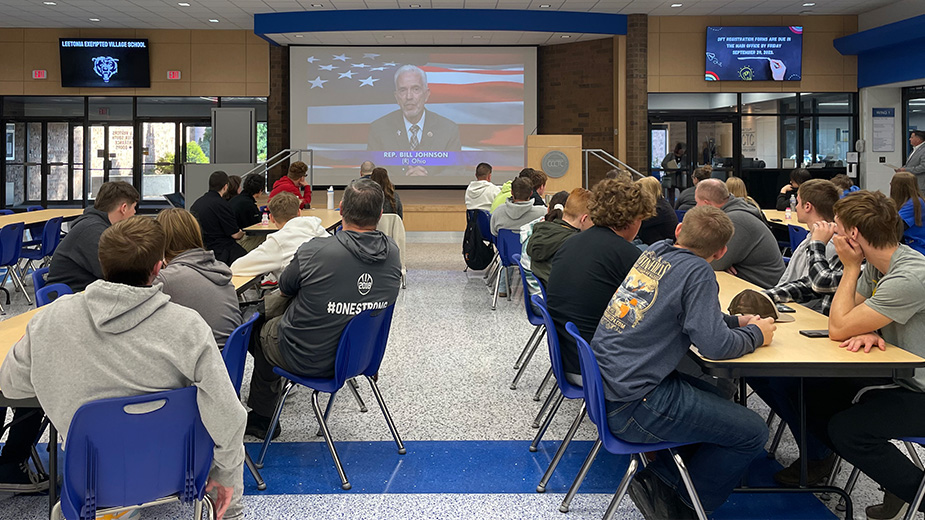

The event is presented by the Columbiana County Educational Service Center’s Business Advisory Council, and in the past it has been attended by U.S. Rep. Bill Johnson, R-6th, who had to welcome the students by video this year due to changes to his schedule in Washington, D.C.

Michelle Fitzsimmons, student services coordinator at the Columbiana County Career and Technical Center, where the event kicked off and ended Wednesday, said about 10 students from each county school participated in the tours and then got a chance to see the CCCTC machining and welding labs, training that can lead to jobs in the manufacturing plants they visited earlier in the day.

“Manufacturing could be either [career center or college]. You need engineers; you need IT people; you need machinists and welders. The goal is for them to see all these different jobs that are out there because manufacturing is the No. 2 employer in our area next to health care.”

Fitzsimmons points out people are retiring, and the CCCTC receives calls from manufacturers looking for people ready to fill those roles, more roles than there are students.

“Not a lot of kids get to go see their future while they are still in high school,” said Bill Stanton, a special education instructor at Lisbon’s David Anderson High School, which sent 10 students but had interest from more. He chaperoned students touring both Ventra and Butech Bliss, where he said they saw employees using large cranes, building machines and then disassembling them and shipping them. “There’s so many opportunities to get into that [the students] don’t even realize within those walls.”

Students who went to Humtown Products brought back souvenir sasquatch sculptures, made out of sand in castings at the plant, which also uses the technology to make automotive parts.

Loyd Hendershot, an East Liverpool sophomore, said he liked seeing that the employees at Humtown worked well together, like friends, and he liked the robotics he saw there.

Andy Miller, an East Liverpool geometry teacher, pointed out the students saw 3D printing, something they do on a small scale in their classroom, being used for larger manufacturing purposes.

“I loved it,” Derion Carnes, an East Liverpool sophomore, said of his experience touring the manufacturing plants. “I liked that they gave us some souvenirs we can take home, and they gave us paperwork that we can [use to] look at our future careers. We got to see how they make the stuff.”

Carnes was among students who said his experiences at Manufacture Your Future left him able to see himself working in manufacturing someday.

Jonas Baker, a sophomore at United Local, was in a group of students who visited Mac Trailer and Hickey Metal, where he saw lasers and robots working to assist the employees.

“A lot of people have a misconception that robots have come to take us over, but really they are here to help us expand industry. And the more robots there are, the faster the job gets done,” Baker said of what he learned during his tours. “It’s not taking people’s jobs – it is just making it easier. [People] can do the more meticulous stuff while the robots can do the stuff that is repeated over and over again.”

Sydney Billy, another United sophomore, was with a group that toured Quality Water and CTM. She said while she was impressed that Quality Water has a healthy work environment, as someone with an interest in art, she found CTM interesting.

“They do designs, and they cut out parts for machinery out of blocks of metal,” Billy said. “There is a lot of programming there, and they also do a lot of welding.”

Pictured at top: Bill Dustman, engineering manager at Ventra’s Flex-N-Gate plant in Salem, talks to students who were touring the area of the manufacturing plant where injection molded parts are robotically painted and baked. The East Palestine students are, from left, Joe Terwilliger, Gavin Knight and Austin Miller.

Copyright 2024 The Business Journal, Youngstown, Ohio.