YSU Students Showcase Projects at STEM Event

YOUNGSTOWN, Ohio – Youngstown State University students showed the product of their yearlong projects Saturday, coming up with a variety of solutions and projects that would be useful in the real world.

About 50 student projects were on display for the College of Science, Technology, Engineering and Mathematics’ STEM Showcase on the YSU campus.

Emilie Brown, coordinator for STEM outreach and scholarships, said STEM students have been participating in this event since its founding in 2007. She said about 150 students are presenting this year.

Many people attend the annual event, Brown said.

“It’s a really good mix of the community, family and friends of the students,” she said. “We [also] work with the admissions office to invite prospective students to come and check things out.”

While the majority of students have been working on their projects for the past academic year, Brown said there are also many students who have been building on projects for multiple years.

Students vary from freshman to senior classes.

“It is open to all STEM students to show their research,” Brown said. “We do have a lot of students from our engineering capstone courses, so there are a lot of senior projects that are showing off their senior designs.”

A lot of students are also members of the Choose Ohio First Program and participate as part of their scholarship, Brown said.

“Some of those [projects] include our competition teams, such as the concrete canoe, the steel bridge and the baja car,” she said. “And then you’ll see some more research based projects.”

Brown said one duo of students looked into finding the COVID virus in wastewater from the residence halls. This project has been ongoing for a couple of years.

“To do these projects and then to present them is important because they are learning a lot of skills,” she said. “It is not just the research and everything, but all of the soft skills they are learning – presentation skills, communication, all those kinds of things.”

Employer partners are also invited to the event, Brown said.

Some students are sponsored by industry partners.

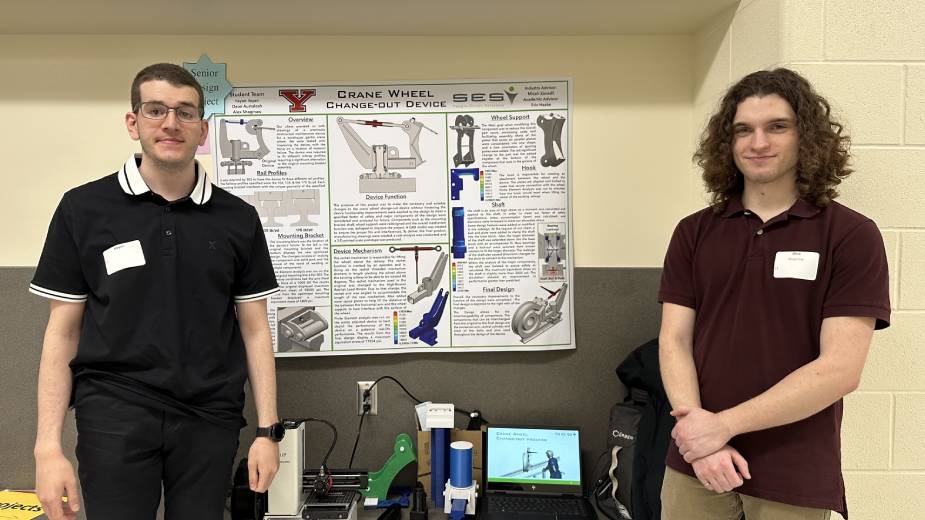

Alex Shanginaw, a senior mechanical engineering student, has been working on a project called Crane Wheel Change-Out Device for overhead industrial cranes in warehouses.

“This was a design that was actually provided to us that had parts with it that were under design,” he said. “They [the parts] failed, and they asked us to make those parts work properly.”

Shanginaw said the group redesigned most of the components of the parts and made sure it was safe. They also used calculations and computer analysis to make sure the stress was reasonable.

Shanginaw and his partners, Ilayan Ilayan and Dean Austalosh, have been working on the project for both semesters of this academic year.

“There were a lot of hand calculations to make sure stress values that we can calculate are safe, and there is a lot of SolidWorks design, which is a lot of the 3D models that you see in pictures here,” he said.

Computer calculations were also made using Finite Element Analysis.

Although the students said they don’t have an exact career picked out for after they graduate, Shanginaw said the project leads them to an industrial warehouse type career.

This project was sponsored by SES LLC.

“They’re basically company projects from actual clients that we sort of experienced what it would be like to have an actual job with the company,” he said. “We met up with a client every once in a while, showed them what we were doing, where we were at and how close we were to being finished.”

Michael Anderson, a sophomore mechanical engineering student, is one of three students working on this year’s project titled Structural Health Monitoring of Active Magnetic Bearing Through the Internet of Things. The project consists of active magnetic bearings, which use electromagnets to levitate bearings as opposed to regular bearings, requiring no physical contact and less maintenance.

“Our research is controlling and monitoring it through the Internet of Things,” he said. “They are all different devices that are connected wirelessly, so you don’t need to have a technician on site to maintain it or monitor it. They can do it with a laptop.”

Anderson said he was working on this project last year, although it didn’t go far beyond lighting up an LED light with the computer. This year, he was joined by two new partners, sophomore mechanical engineering students Alayna Cuevas and Christine Zheng.

“This year we did more with the testing device with the magnetic bearing,” he said.

Zheng said through the project, they learned a lot about coding.

“It’s a lot harder than most,” she said. “These wires have to be connected so specifically. If one thing is off, it’s all wrong.”

Because they are mechanical engineering students, Cuevas said it presented a bit of a challenge.

“It is more electrical based, so it is different,” she said.

The group said they believe it is important to do projects like this because of the collaboration.

“I like the hands-on aspect,” Zheng said. “And it’s research too. That’s always good, and I’ve always been interested in that and I’ve always been hand-on, as well, so this was a good application of all of that.”

Zheng’s project last year 3D printed pieces and compared them to real manufactured products.

Cuevas said the projects are part of a four-year program. Students are assigned projects and groups each year after completing surveys to see what would best suit them.

Last year, Cuevas was paired with a civil engineering group that worked on a retaining wall project for the church on Wick Ave.

“The wall was failing, so we made a cost estimate of three different options to replace it, fix it or leave it if it eventually fails,” she said.

While a lot of people know what STEM stands for, Brown said, many people are still unsure of what they can do with those degrees. She said this event is a good event to help students “connect the dots” of the opportunities available to them.

“I think it is really important for people to know the work that our students are doing,” Brown said. “They are doing some incredible stuff, and it’s hard to get the word out about all of the cool stuff that they are doing. For one, it is really good for people to know what our students are doing, but also it is important for STEM in general because it is such a growing field and there is so much need.”

Pictured at top: Senior mechanical engineering students Ilayan Ilayan, left, and Alex Shanginaw present their senior project of crane wheel change-out devices at the STEM Showcase on Saturday.

Copyright 2024 The Business Journal, Youngstown, Ohio.