WARREN, Ohio – Zach Cowher wants to fuse his knowledge with teenagers who are ready to explore the world of welding, and for good reason.

The career and technical education teacher for Warren G. Harding High School recognizes the massive skills gap that needs to be bridged.

According to a March 2020 study by the U.S. Chamber of Commerce, “74% of hiring managers agree that there is a skills gap in the current labor market, with 48% saying that candidates lack the skills needed to fill open jobs.”

To address that gap, as well as local manufacturers’ need for workers, the Warren high school offers an accredited welding program that provides students with the skills needed to pursue an apprenticeship with an employer after high school, Cowher says. It provides graduates with a potential career without having to amass student loan debt or struggle to find work.

“You have an 18-year-old on the job making $36,000 a year,” Cowher says.

Giving the Mahoning Valley a prepared workforce is the basis of this program, adds Harding High School Principal Dante Capers. “I’m excited to see the students’ passion for their future and having definitive steps for a 16-, 17-, 18-year-old knowing what they want to do when they’re 19 and 20,” he says.

In 2016, a grant from Arconic in Niles to Warren City Schools supported the welding and construction program. The following year, half of the woodshop at Harding was converted into a welding laboratory.

Four Lincoln Electric welding labs were installed in 2018 for training purposes. The Expanding Opportunities for Each Child grant program provided two Lincoln Electric virtual training welders. A third simulator was purchased through Title I funds in the 2020-21 school year, with two more on the way, Cowher says. Students have logged more than 100 hours on those simulators.

Those virtual systems train students like Brandon Keen, a junior, on knowing the appropriate gas mixtures and how to measure before going to a live weld. “It’s a really good machine,” he says.

Woodshop originally attracted Keen in the eighth grade. But he also toured the high school’s welding facility and was quickly enamored with the sights. His brother and grandfather were welders and he aspires to be a pipeline or construction welder.

“When you start to do it, it’s just great,” he says. “It’s therapeutic. When you get done, you see your weld. You’re proud of it. It’s just great.”

The simulators train students on the correct handling of the welding tools and how to fixate to the proper angles, providing teachers with immediate feedback on each student’s progress, says Suzette Jackson, assistant curriculum director for grades six through 12 at Warren City Schools.

“Those pieces all help the students develop their muscle memory,” Jackson says. “By the time they get into one of the big four welding booths, they’re ready to go ahead and begin the live welds.”

Safety is the emphasis, not only for welding, but other manufacturing jobs. Students complete a mandatory 10-hour OSHA certification program, which takes about a month of class time, Cowher says.

“They work in that area without putting themselves or others in danger,” he says.

Cowher calls himself a facilitator and guide to those taking the courses. There’s only so much a student can absorb from reading a textbook and watching someone do the work. They have to get hands-on experience, eventually learning how to properly join metal together.

Ajax Tocco Magnethermic Corp. in Warren provided leftover steel pieces for students to use for training. The students use them to learn how to perform different welding patterns, working on various positions with metals up to ¾-inch thick.

The students will attempt a T-shaped fillet weld with two metallic pieces. The strength of the bonded joint is vigorously tested, Cowher says, the same testing required when applying for certification with the American Welding Society.

“We’re training our students to pass AWS welding,” Cowher says. “The other certifications are not quite as stringent. We’re shooting for AWS. Even if they fall short, they’ll be overqualified for the other certifications.”

The school’s welding lab is capable of supporting flux-cored, gas metal, gas tungsten and shielded metal arc welding. Each of these will be available as separate industry recognized credentials for the 2021-2022 school year.

The plan is to have first-year welding students earn the qualification and then work toward the certification their second year, which increases their earning potential once they leave high school.

“Not only are they graduating meeting their core requirements, but they’re graduating with a credential that says ‘I’m ready to enter this workforce,’ ” says Warren City Schools’ Jackson.

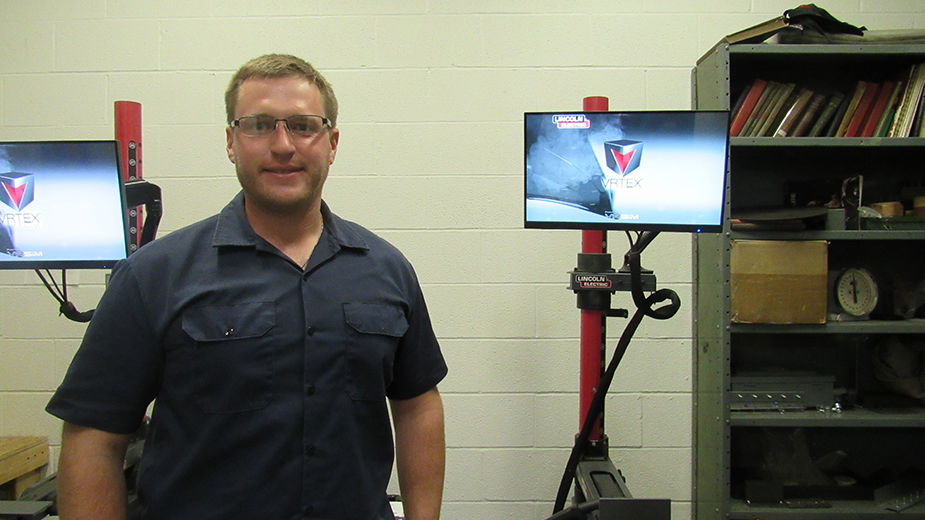

Pictured: Zach Cowher, Warren Harding High School’s technical education teacher, stands next to one of the welding simulators at the school.