Safety Council Seminar Focuses on Secure Lifting

YOUNGSTOWN, Ohio – As Al Abel made his way to Youngstown Wednesday morning, he drove past several large pieces of lumber that had fallen onto the road. The exact details of how they got there were a mystery, but that they were there at all was problematic.

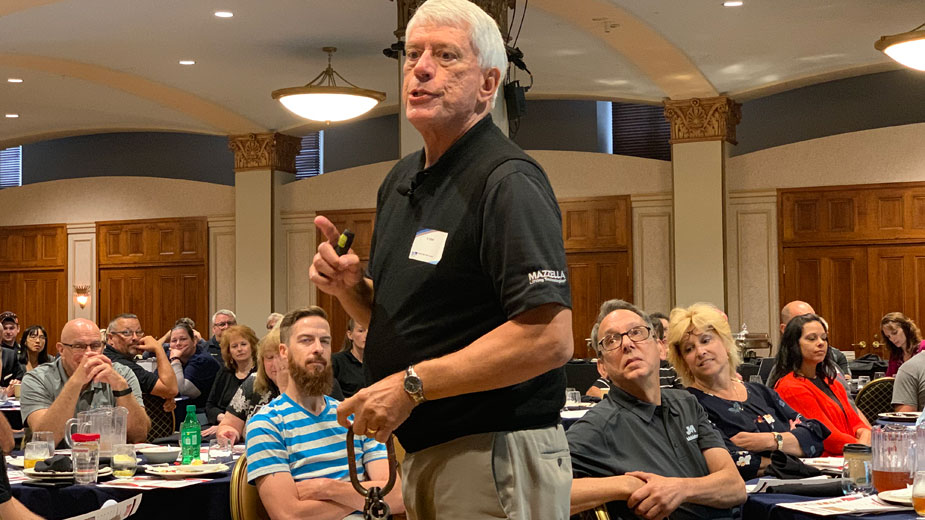

“Once I came to the turnpike, I could not believe how many large pieces of lumber were on the road as I was driving,” said the lifting specialist of 24 years from the Cleveland-based Mazzella Lifting Technologies. “I bypassed probably six to eight pieces of sizable lumber on the ground that a truck dropped.”

Without proper care, inspection and use, the slings and below-hook lifting devices companies use on a daily basis can result in injury and death. At the Mahoning Valley Safety Council’s program July 17, Abel focused on how to plan – and secure – every lift.

“In my world of cranes, rigging and lifting, it’s all about inspection of your rigging gear, hardware and cranes, how do we connect to the load and do we make sure we do that in a safe manner,” he said. “Before you make a lift, you need to think through what you need to do before you make that lift.”

Safety is important in any realm of business, said Karen Stacey, executive director of the leadership and safety programs. The safety council tries to offer diverse topics to all safety council members every year.

“This is very important to keep your workers safe in the workplace, to keep them away from harm and to help them go home at the end of the day,” she said. “That’s everyone’s goal.”

Companies who sent representatives received a benefit on their Bureau of Workers’ Compensation plan while also gaining valuable insights.

“You have companies a part of the BWC in this region and not all of them are manufacturing companies, so you’ll have schools, hospitals and stuff in here,” he said.

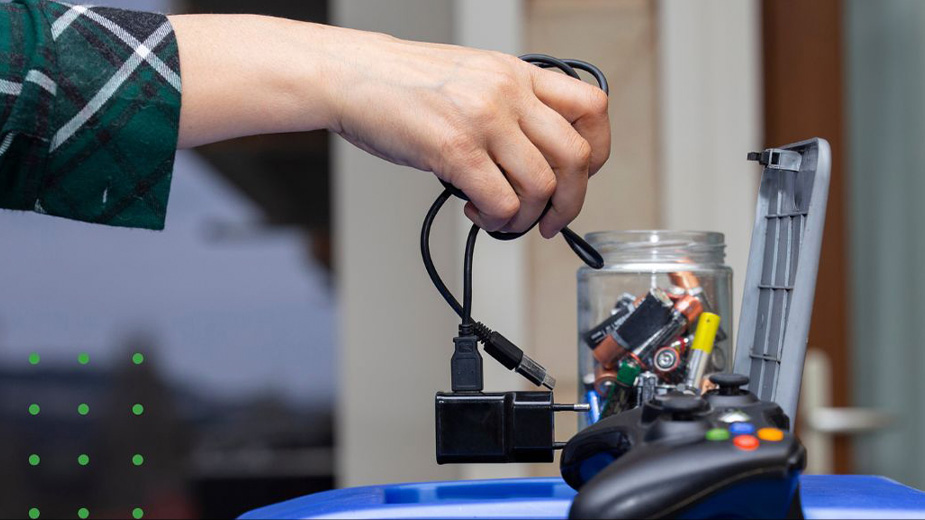

Whether lifting and rigging is done in schools, manufacturing companies or at home, considerations should include how much the object weighs, its inspection, what kind of training is involved, sling angles, load securement and its center of gravity, Abel said. To showcase proper methods, Abel brought with him interactive displays featuring chains, ropes and slings.

“Even from a personal standpoint, we need to keep our eye on our stuff even when you’re driving in your car,” he said. “If you suspect an issue, you need to get it addressed. People in companies, when they run their crane, it’s about to lift up five or 10 tons. It better be running correctly.”

As an employee, responsibilities as either a crane operator or rigger include making sure they’re comfortable with both the machinery and attached equipment. The Occupational Safety and Health Administration also requires any company employing crane operators and riggers to have proof they have trained their employees properly.

“All their people need to be trained,” Abel said. “It’s that companies responsibility to provide that training. If they do it internally or hire someone like me to come in and support that, that’s up to them, but the significance is that they want to avoid any kind of workers comp claim and lost time injuries.”

To continue learning about rigging and lifting, to keep proactive within their business and to have a proper use of risk management, attending an interactive program like this will only benefit a business and its employees, Abel said.

Other items on the lifting plan list included to not walk or work under a load, paying attention to lift height, watching for slings against sharp corners and the condition of the equipment being used. Abel has hopes of employees taking back what they learned to their company, no matter their department, whether human resources or the shop floor.

“Even if they just take it home,” he said. “I hope something we say today will kick in that, ‘Hey, I need to think about this before I do this.’ Like when somebody is hauling a boat, pulling a camper, they got chains, ropes, tiedowns. Are they inspecting those things, are they making sure everything is tied down properly and don’t take stuff for granted.”

Pictured: Al Abel of Mazzella Lifting Technologies was the featured speaker at the Mahoning Valley Safety Council’s seminar Wednesday.

Copyright 2024 The Business Journal, Youngstown, Ohio.