YOUNGSTOWN, Ohio – Brilex Technical Solutions, Youngstown, reports 2021 was a year of steady growth with a very exciting ending.

The company is an engineering group that specializes in standard and custom solutions for industrial equipment used in steel and aluminum production, scrap processing and custom turning applications.

“We saw significant growth throughout the year, particularly in our material-handling and turntable product lines,” says Joshua Vitale, general manager. “We ended the year on a high note by securing the largest order in BTS history.”

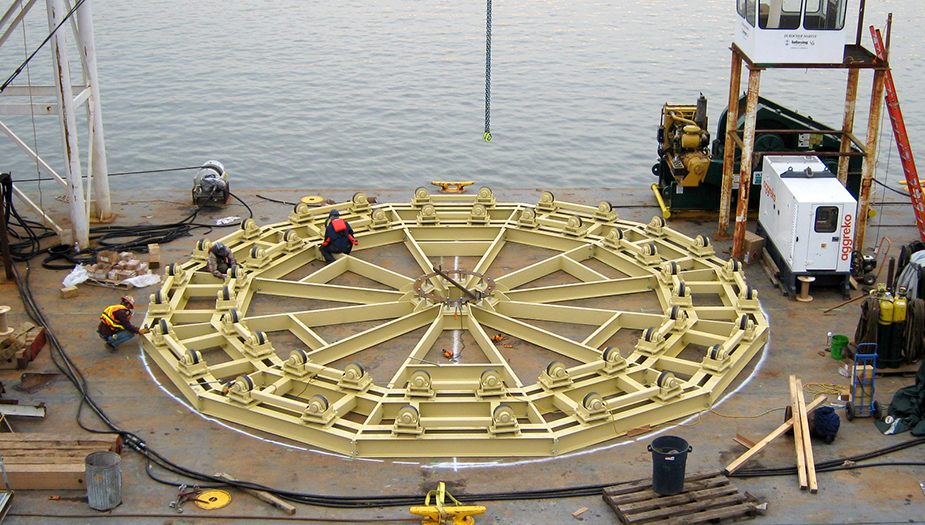

The order is an exclusive contract with Caldwell Marine International for the design and manufacture of marine cable-laying turntables. BTS will help deliver clean energy to the New York metropolitan area as part of the Champlain Hudson Power Express Project.

A fleet of six turntables will be used to lay approximately 339 miles of power transmission cable that will deliver 1,250 megawatts of hydro and wind energy to power more than a million homes. Approximately 198 miles of that cable will be installed underwater beneath the entire length of Lake Champlain, starting from its northern shore in Quebec, running south under the Hudson, Harlem, and East rivers and terminating in Astoria, Queens, New York.

“We are proud to be an integral part of such a high-profile project,” says Vitale. “Our team has worked very closely with Caldwell Marine throughout this process. And we are excited for our role in bringing this renewable energy transmission project to fruition. This marks an important step in establishing our footprint in the cable, sub-sea, and wind power marketplace.”

Brilex Technical Solutions introduced several product innovations into the aluminum extrusion marketplace in 2021, including high-speed, multi-axis billet loader designs to replace outdated handling systems. BTS also has a patent pending for its proprietary butt retrieval system, which was designed and engineered to provide a safe and effective method of removing butts directly outside of the press frame.

“With alternative and offshore wind market growth, and new steel mills coming online across the country, BTS is excited for 2022,” says Vitale. “We will continue to exceed our customers’ expectations and expand our business by proving our value as new opportunities arise.”